Applying a little physics — Mechatronics option adds experiential learning to science program

The senior physics lab at UFV is bursting with energy on a Monday afternoon. It’s team time. There’s no formal lecture taking place; this is the time when the students in the Engineering Physics in Mechatronics program work on their group projects.

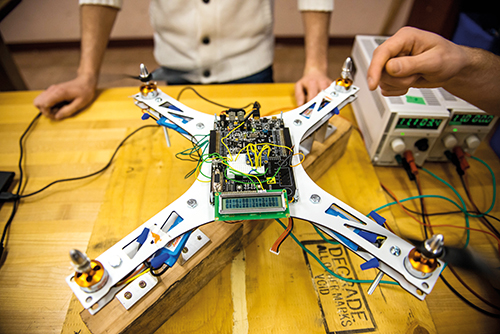

One team of four students is working on a quadcopter, built from scratch in the hopes that this baby will fly someday soon. For now it’s bolted to a support, because one small tilt could ruin months of work.

Team member Perrin Waldock is stoked by the hands-on nature of the project.

“It’s really cool watching stuff actually happen and being involved in it from the beginning,” he says. “It’s one thing to be looking at equations on a board, and it’s way cooler to plug in a motor of something that you’re involved in building and see it do what you want it to do. I had done programming before, but never with motors. That’s the best part — applying the physics we’ve learned. The worst part is the frustration when you put hard work into something and things don’t work out anyway.”

As he and Dennis Schimann work on the quad-copter itself, teammate Nikola Trotzuk works on the controller and Alex Vogt works on ultrasonic sensors for obstacle avoidance.

“If the quad copter gets too close to objects, this will tell it to stop,” he notes.

Another team, not present in the lab today, is working on a breathing phantom, a device that simulates breathing for use in radiation therapy.

These physics students working on real-life challenges, complete with nuts, bolts, circuitry, joysticks, and electronic transmitters, represent a concerted effort by the UFV Physics department to add an applied component to its menu.

These physics students working on real-life challenges, complete with nuts, bolts, circuitry, joysticks, and electronic transmitters, represent a concerted effort by the UFV Physics department to add an applied component to its menu.

“We found that we were doing a very good job of graduating physics majors, but most were in the theoretical physics realm — they tend to do very well and go on to either graduate studies or teaching careers,” notes Dr. Tim Cooper, a physics professor who guided the development of the program. “But we weren’t offering enough for students who wanted to go apply their physics knowledge to industrial workplaces. We wanted to give them more hands-on skills.”

The solution? A Engineering Physics diploma in Mechatronics, a two-year credential that can be taken on its own after one year of physics and math prerequisites, or blended in with a UFV Bachelor of Science in Physics degree.

Dr. Lin Long, an engineer with significant industry experience in both China and Canada, was brought on board to teach the mechatronics component of the program. For four semesters, students in the program combine physics with computing, engineering, and electronics courses. For some of their courses, they use the electronics and prototyping labs in the UFV Trades and Technology Centre, forging new connections between trades and science.

One of these is a week-long intensive summer course, taught in part by Dean of Applied and Technical Studies John English, where students learn how to use welding equipment, laser cutters, 3D printers, and more.

It all culminates in a capstone project where students apply what they’ve learned to an industrial-type project. The capstone projects for the inaugural class have included:

- An automatic honey extraction system for a commercial honey operation

- A laser alignment system for medical linear accelerators at the BC Cancer Agency

- A robotic arm

- An automated sorting system that could tell one colour of Smarties candy from another

- A greenhouse monitoring system that would turn fans on when sensors detected too much humidity.

For some, the capstone project led directly to employment. Cameron Appeldoorn and Brandon Vangenderen, for instance, are now working for the BC Cancer Agency, refining the testing device for medical linear accelerators.

Breathing phantom system — In collaboration with the BC Cancer Agency

This system is a medical device used in the quality assurance procedure for improving lung cancer radiotherapy. The lung motion during the inspiration cycle makes it very challenging for oncologists to treat the moving target lung tumor. The breathing phantom system simulates the motion of the target tumor in synch with the patient’s breathing cycle. This means the radiation treatment can be delivered to the target tumor more precisely. UFV Mechatronics students designed the lung phantom vertical motion mechanism, and designed and programmed the main controller to synchronize the motion of lung phantom and target tumor, allowing for more accurate and effective treatment of lung tumours.

Quadcopter drone

A hobby drone project that students initiated. Instead of buying the modules from the market, they designed the on-board controller and remote controller from scratch. They are adding obstacle avoidance and autonomous function into the drone so that it can fly autonomously or manually-controlled.

Breathing phantom system — In collaboration with the BC Cancer Agency

This system is a medical device used in the quality assurance procedure for improving lung cancer radiotherapy. The lung motion during the inspiration cycle makes it very challenging for oncologists to treat the moving target lung tumor. The breathing phantom system simulates the motion of the target tumor in synch with the patient’s breathing cycle. This means the radiation treatment can be delivered to the target tumor more precisely. UFV Mechatronics students designed the lung phantom vertical motion mechanism, and designed and programmed the main controller to synchronize the motion of lung phantom and target tumor, allowing for more accurate and effective treatment of lung tumours.

Robotic arm

2016 project

Students designed and programmed the controller for a robotic arm so the arm can identify different colored objects, pick up the objects, and sort them into different piles. Possible future applications in berry production or manufacturing.

Honey extraction de-boxing module

2016 project — In collaboration with the Worker Bee Honey Company

This module is part of the honey extraction process, where the honey super (a box with nine honeycomb frames inside) will be delivered to the de-boxing platform and then the nine honeycomb frames will be pushed up

to a rail automatically.

Spinoff collaboration

UFV has received a National Science and Engineering Research Council Collaborative Research and Development grant to work with Worker Bee Honey Company on an automated honey extraction system.

Four current Engineering Physics in Mechatronics students will work on the mechanical design, control system design, and PLC (programmable logic controller) program for this project. The students will collaborate with the industry partner, industry consultants, and faculty researchers.

Automating mechanical quality assurance tests for medical linear accelerator

2016 project — In collaboration with the BC Cancer Agency

In radiotherapy cancer treatment, patient positioning is critical for ensuring the radiation beam is delivered to the target tumor. This positioning is guided by a system of lasers embedded in the walls and ceiling of a treatment room, which are prone to slight shifts over time, requiring daily checks and periodic calibration. Currently, this laser alignment is controlled manually. In this project, UFV students designed and programmed a device that uses a system of cameras and computer vision algorithms to perform quality assurance tests on the medical linear accelerators. The system automatically realigns the patient positioning lasers. Their work means shorter test completion times and higher accuracy than manual measurements, ensuring patients receive the most accurate treatment possible.

Originally published in the Spring 2017 edition of UFV Skookum magazine.